Not known Incorrect Statements About Motorcycle Parts New Zealand Specialists

Motorcycle Parts New Zealand Specialists Things To Know Before You Get This

Table of ContentsGetting My Motorcycle Parts New Zealand Specialists To WorkWhat Does Motorcycle Parts New Zealand Specialists Do?The Ultimate Guide To Motorcycle Parts New Zealand SpecialistsTop Guidelines Of Motorcycle Parts New Zealand SpecialistsMotorcycle Parts New Zealand Specialists - The FactsMotorcycle Parts New Zealand Specialists Things To Know Before You BuyThe Best Strategy To Use For Motorcycle Parts New Zealand SpecialistsMotorcycle Parts New Zealand Specialists - An Overview

So, get to out to one of our experts today.CNC machining modern technology is swiftly becoming the centerpiece of various production procedures around the globe as a direct result of its numerous benefits over other techniques. Furthermore, the sectors that make bikes have actually jumped on board with this pattern. One of the most ingenious companies are now establishing their engine parts and wheels making use of machining methods originally created for motorbike components.

You may be questioning why we make use of. Now that we have your focus let us explain the rationale behind this modern growth in the motorcycle production industry.

Unknown Facts About Motorcycle Parts New Zealand Specialists

Additionally, you have total control over the look of the parts, even to the minute details. Occasionally, motorcyclists might make a decision to spruce up their adventure by installing aftermarket elements or changing the bike's transformation. Once once again, computer system mathematical control (CNC) machining is one of the most useful method. Upgrades might be of any type and style you want.

The Motorcycle Parts New Zealand Specialists PDFs

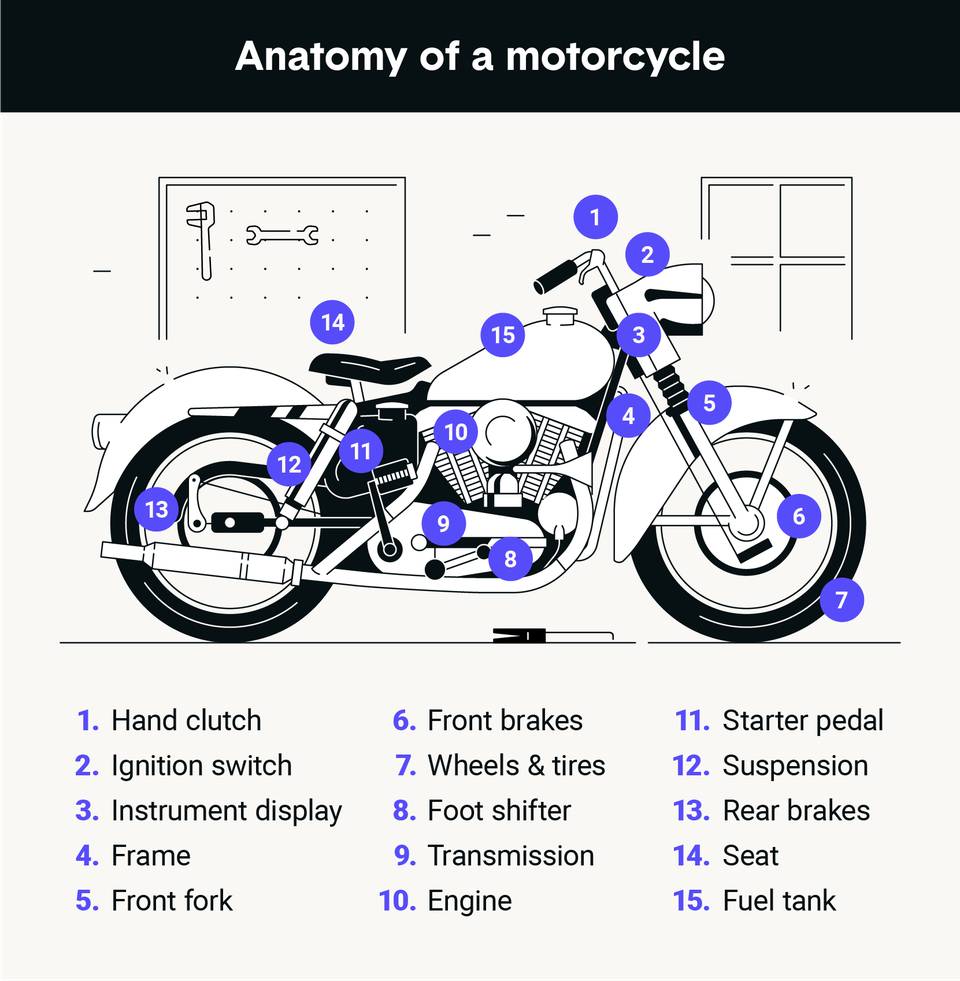

CNC machining may be utilized to make practically all of a motorcycle's metal and plastic elements. To proceed, we'll discuss a number of machined components for bikes. In comparison to those on vehicles, wheels on motorcycles often tend to be more apparent. Consequently, the bike's appearances may be boosted with the proper modification of these wheels.

When tailoring the wheels, the disks are where the emphasis must be. Most of them are constructed out of light weight aluminum. Aluminum alloys are widely known for the superior machining abilities that they possess. Milling procedures are utilized to get the wanted degree of wheel personalization. One more element of the motorcycle that might be personalized is the tires.

Motorcycle Parts New Zealand Specialists Things To Know Before You Buy

When it involves a lorry (or a motorbike), the most important component is the engine. A number of individuals mention it as the "heart" of the vehicle. On the other hand, the camshaft, the cylinder head, and the pistons have a tendency to be detailed and call for styles with a high degree of accuracy.

Usage just top notch items, nonetheless, considering that these lights are vital for the safety of motorcyclists and other motorists or individuals on the road, especially at night. Motorcycle headlights have 3 major parts: the bulb, or light resource, the lens, and the real estate.

Milling procedures with a perfect coating would certainly cause the lenses having a reflective high quality that resembles that of a mirror. The cover, on the various other hand, is not made up of breakable materials; rather, it is built out of hard polymers that can be machined right into more complex patterns.

Motorcycle Parts New Zealand Specialists Things To Know Before You Buy

Motorbike manufacturers often cast these elements, but just for the production of bespoke parts. Machining on 5 axes in today's globe is the methods by which any type of style shape may be understood.

Select Runsom for your tailored motorbike parts! We have the capacity to produce complicated and elegant components making your motorcycle matchless.

Below are a couple of instances of steels frequently used in motorbike element machining. Light weight aluminum is the primary material used by firms specializing in generating custom-made motorbike elements to produce many of these components - Motorcycle Parts New Zealand Specialists.

Zinc describes one more metal that is extremely light in weight and has wonderful machining qualities as a result of its high mechanical stamina. This product may be created right into virtually any shape and maintains its measurements well. Also mission-critical parts that need a high level of precision might take advantage of their usage.

Things about Motorcycle Parts New Zealand Specialists

One more metal that sees hefty use in the production of CNC-customized parts is magnesium. It is amongst the lightest steels that are now obtainable and has outstanding machinability attributes and strength compatible with its reduced weight. One of the disadvantages of more helpful hints magnesium is that its dirt may quickly ignite.

Because of its premium machinability and weldability, stainless steel is an alloy that is particularly fit for CNC procedures. Along with this, they have terrific deterioration resistance and a high visual appeal. Their most typical usage in creating numerous motorbike parts is link fasteners, such as screws and bolts. Their reduced sensitivity to oxidation and corrosion makes them excellent for this use.

Motorcycle Parts New Zealand Specialists Can Be Fun For Anyone

It seems that CNC turning and milling are the foundational processes. In enhancement, it calls for maintaining bars of product, most usually plastic or steel, in setting and then twisting a reducing tool to eliminate sections of the product as the product is transformed.

These approaches are just as essential and produce elements with high precision and consistent top quality. The check out here procedures aid boost the total high quality of the machined bike parts.

Excitement About Motorcycle Parts New Zealand Specialists